Because customer satisfaction is our main goal, OCEA Industries guarantees to provide you tank ends with an optimal finished product, with quality required internally and reputed by the external authorities.

Traceability

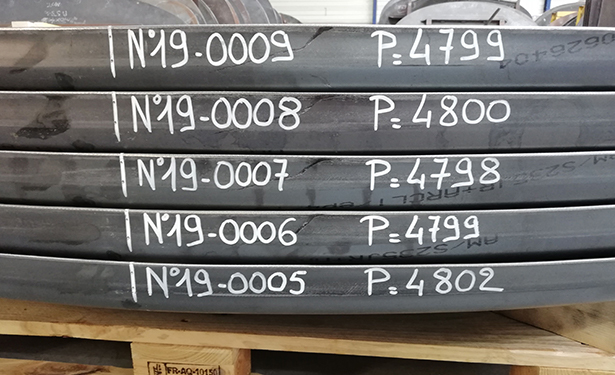

In order to provide you with an optimal traceability, each tank end has its own and unique number.

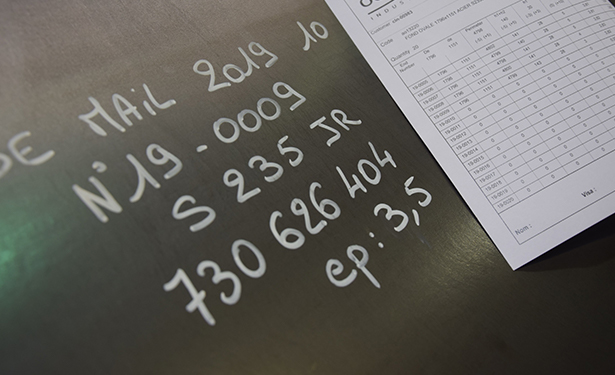

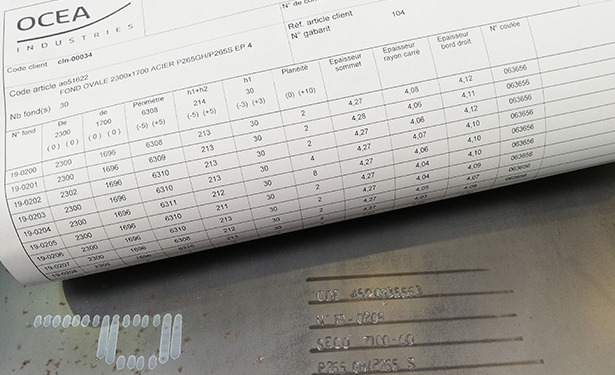

Inside of the tank end, we indicate, with a pencil or by cold stamping, your references (order and product), the unique number of the tank end, the material alloy, the batch number and the plate thickness. We can add some other information if necessary.

Tolerances & Inspection

We restrain our tolerances in order to guarantee you a regularity in the delivered products as well as save you time by facilitating the swift insertion of them in your barrels.

Each tank end is checked in accordance with the tolerances agreed together: shape control, perimeter, flatness, thicknesses… We provide you with a control file for each order in which you can find all these values.

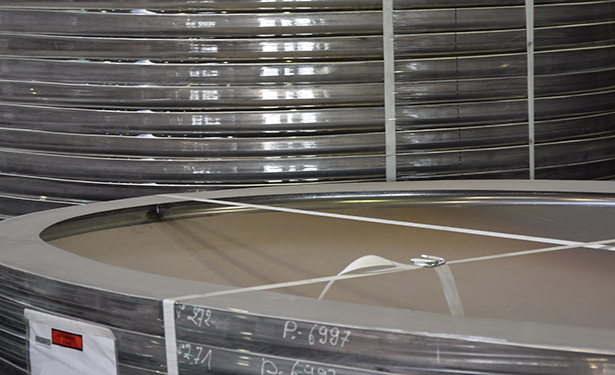

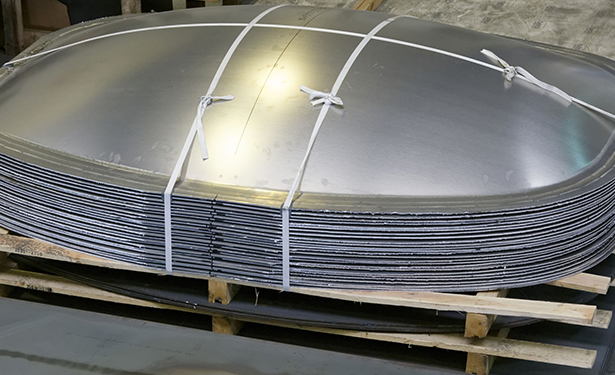

Packaging

Tank ends pallets are protected with a plastic film and held together by a strap. We usually put up to 25 aluminium tank ends or up to 15 carbon or stainless ends per pallet.

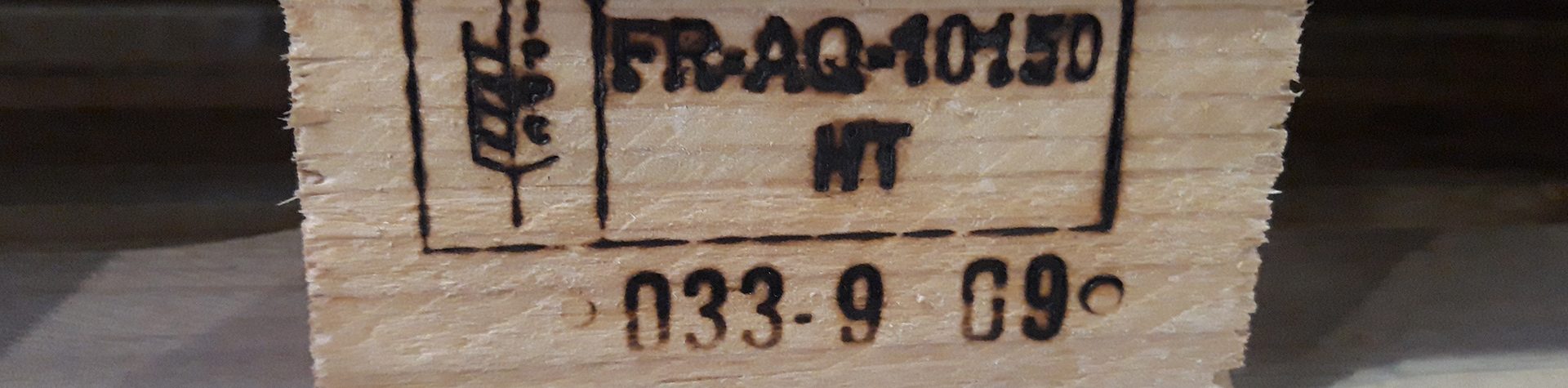

For exportation, pallets are always treated according to ISPM15.

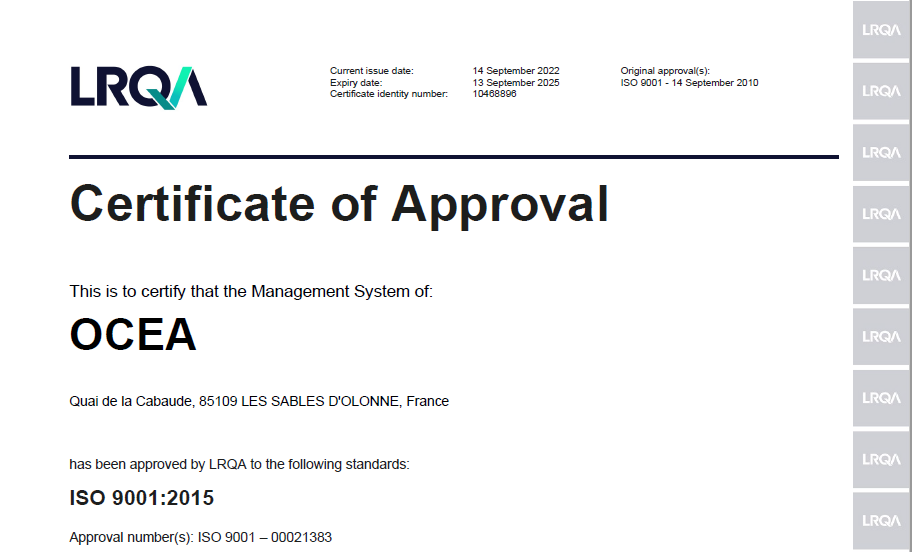

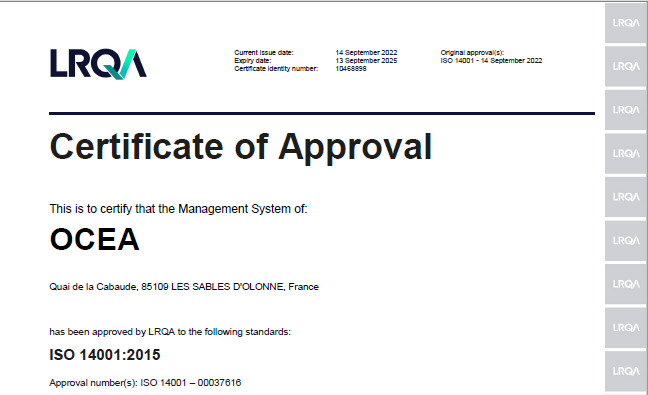

Certifications

For many years, external control organizations audit OCEA’s industrial process. They renew their confidence in our products and process every time.

We are certified by :

- TÜV for the manufacture of tank ends regarding ADR, RID, and EN 13094

- TDT for Poland

- ISO 9001 :2015

- ISO 14001 :2015